Precision control in industrial automation applications is made possible by the Rockwell Automation Micro820 Controller’s cutting-edge features and capabilities, which improve its functionality. The Micro820 Controller has a number of important cutting-edge features, including:

High-Speed Counters:

High-speed counters that are already present in the Micro820 can be utilised to keep track of and keep an eye on fast-moving events like pulses or encoder inputs. These counters enable precise measurement and management of machines or processes that move quickly.

- Counting Speed: The Micro820’s high-speed counting capability enables accurate tracking of pulses or events that happen quickly. Depending on the type, the counters can handle counting frequencies as high as MHz (megahertz) or as low as kHz (kilohertz).

- Input Types: The Micro820’s High-Speed Counters may receive a range of input types, including discrete signals, pulse signals, digital signals, and outputs from encoders. The inputs can accept pulse or event signals from a variety of sensors, encoders, and other devices.

- Counter Modes: To meet the needs of varied applications, the Micro820 has a variety of counter modes. Up-counter, down-counter, up/down counter, or quadrature counter are examples of common counter modes. Based on the input signal, these modes control how the counter increases or decreases.

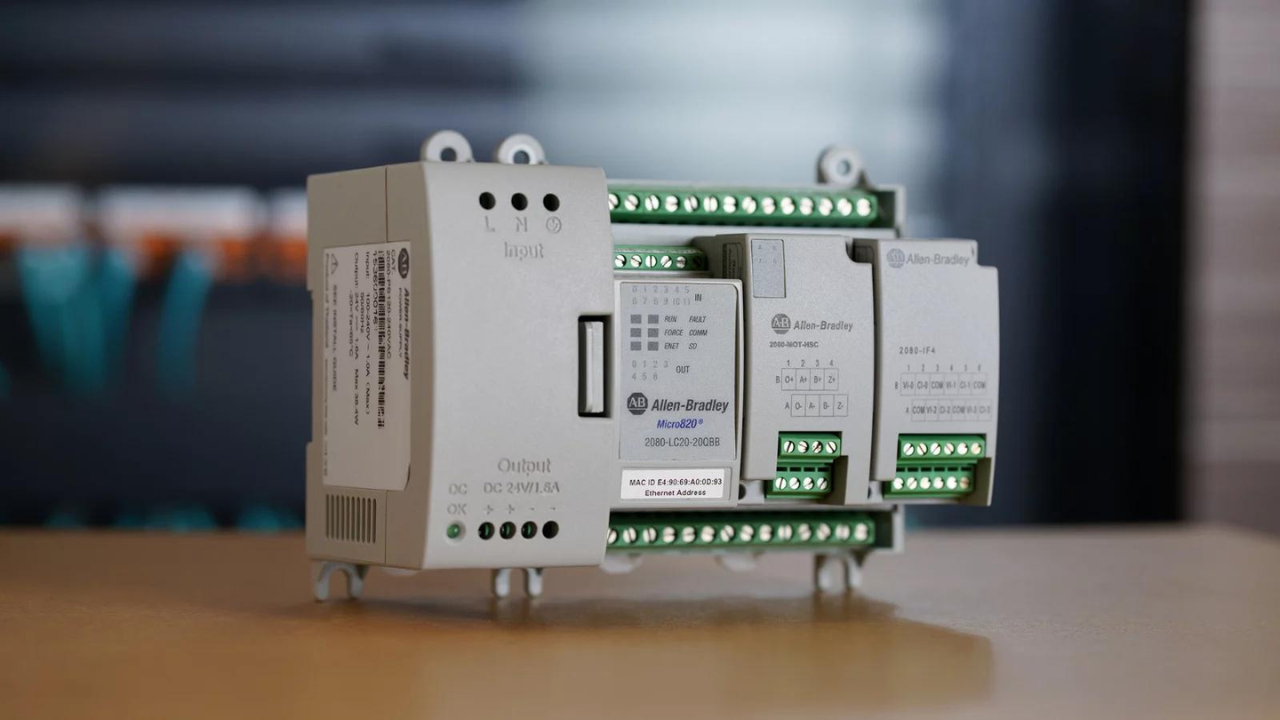

Read: Rockwell Automation 2080-LC20-20QBB Micro820 Programmable Controller

Analog I/O:

The Micro820 can connect with analogue sensors, transmitters, and actuators because to its analogue input and output capabilities. This makes it possible to precisely manage and monitor analogue signals like flow, pressure, temperature, and more.

- Analog Inputs: A variety of analogue signals, often in the form of voltage or current, can be fed into the Micro820’s analogue input channels. Temperature sensors, pressure transducers, and level sensors are just a few examples of the analogue sensors and transmitters that can be used with these inputs. For further processing, the controller transforms the analogue signals into digital values.

- Analog Output: Additionally, the Micro820 offers analogue output channels for producing analogue control signals. These outputs can be coupled to analogue actuators like proportional valves, variable frequency drives (VFDs), and other machinery that needs constant control signals. Based on the digital values the controller provides, the analogue output channels produce accurate analogue signals.

PID Control:

PID (Proportional-Integral-Derivative) control loops, which are frequently used for accurate process control, are supported by the Micro820. The built-in PID command automatically modifies output values based on feedback from sensors to maintain control over variables like temperature, pressure, or level.

The Micro820 provides channels for analogue inputs that can accept a variety of analogue signals, most frequently in the form of voltage or current. Temperature sensors, pressure transducers, and level sensors are just a few examples of the analogue sensors and transmitters that can be used with these inputs. For further processing, the controller transforms the analogue signals into digital values.

The Micro820 additionally has analogue output channels that can be used to provide analogue control signals. These outputs can be coupled to analogue actuators like proportional valves, variable frequency drives (VFDs), and other machinery that needs constant control signals. Based on the digital values the controller provides, the analogue output channels produce accurate analogue signals.

Motion Control:

Applications for the Micro820 in motion control include servo and stepper motor control. Precision positioning, velocity control, and coordinated motion are all made possible by the provision of advanced motion control instructions and features.

- Motion Profiles: You can create and use motion profiles with the Micro820 to designate the preferred trajectory or path for the controlled device. Smooth and controlled motion is made possible by motion profiles, which specify factors including velocity, acceleration, deceleration, and jerk.

- Position Control: With the help of the Micro820, you may precisely control the position or placement of a device. The controller determines and applies the appropriate control signals to accomplish precise positioning by using the intended target position as input.

Data Logging and Historian:

The Micro820 is equipped to record data and deliver it to external storage systems or store it internally. For purposes of analysis, troubleshooting, and gathering historical process data, this capability is beneficial.

- Data Logging: The Rockwell Automation Micro820 controller offers the ability to log data from a variety of sources, including internal variables, analogue inputs, and digital inputs. The controller can be set up to log data periodically or when particular events take place. Process variables, timestamps, alarms, and other pertinent data may be included in the logged data.

- Historical Data Storage: To save the logged data, the Micro820 includes internal memory or external storage choices like SD cards or USB drives. Depending on the particular type and setup of the controller, the storage capacity may change. The historical data can be easily transferred to and analysed on other computers or devices thanks to external storage options.

Integrated Web Server:

The Micro820 has a built-in web server that provides web browser-based remote monitoring and control of the controller and the associated devices. With this functionality, monitoring and troubleshooting are made simple from any compatible device.

- Web-Based Configuration: Using a web browser and the web server, you can change the Micro820’s settings and parameters. Without specialised software or programming tools, the web-based configuration interface can be accessed from any device linked to the same network as the controller.

- Remote Monitoring and Control: The Micro820 may be monitored and controlled remotely from any location with network access thanks to the built-in web server. Using the online interface, you can keep an eye on variables, alerts, and device status in real-time. Through the online interface, you may also initiate activities or control outputs remotely.

The Micro820 Controller’s cutting-edge features enable customers to develop sophisticated control methods, handle challenging automation jobs, and interact with a variety of devices and systems, thereby improving the functionality and performance of their industrial automation applications.

Asteam Techno Solutions Pvt. Ltd. is a leading and preferred solution provider for all kind of Industrial Automation requirements in the field of Process and Power Automation. Established in 2017, Asteam Techno Solutions is an ISO 9001: 2015 certified company, having its Design, Manufacturing & Repair facility located in Surat, Gujarat, India and provides total integration under one roof.